Spotlight: Professor Christopher Depcik

- Kelly Senecal

- Mar 28, 2019

- 4 min read

One of the main objectives of #HugYourEngine is to shine a spotlight on individuals who are helping make internal combustion engines cleaner and more efficient. This spotlight is on Christopher Depcik.

Dr. Christopher Depcik is a Professor in the Mechanical Engineering Department at the University of Kansas (KU). In addition, he has a Courtesy Appointment in the Aerospace Engineering Department. Prior to joining KU, he worked at the University of Michigan (UM) as a post-doctoral research fellow. He received his Ph.D. in Mechanical Engineering from UM (2003), as well as an M.S. in Aerospace Engineering (2002), and an M.S. in Mechanical Engineering (1999). He received his B.S. in Mechanical Engineering from the University of Florida (1997). Dr. Depcik’s laboratory conducts research revolving around a sustainable approach to energy and the transportation infrastructure. This includes analysis of biofuels, exhaust aftertreatment devices, and energy recovery potential. His group has published over 100-refereed articles and Dr. Depcik received the Society of Automotive Engineers Ralph R. Teetor Award for his transportation-related research and educational activities.

Kelly Senecal (KS): When and why did you get started in combustion research?

Christopher Depcik (CD): My interest in combustion research started in earnest at the University of Michigan when I took Prof. Dennis Assanis’s Internal Combustion (IC) Engine class. Prior, I had always found thermodynamics interesting and Prof. Assanis contained an amazing capacity of taking these fundamentals and converting them into practice. From the first day of class, I was hooked on seeing how theory can play a large role in improving the performance and emissions of internal combustion engines.

KS: What are you working on now?

CD: Our laboratory’s research includes understanding the entire facet of fuels from their production through tailpipe emissions including catalytic conversion. For example, funded efforts include a life cycle analysis of the production of biodiesel from soybeans involving land usage along with generation of oil and biodiesel. Subsequent combustion analyses of this biodiesel, both in the conventional and low temperature combustion regimes, helps to highlight its potential as an alternative to fossil fuels. Furthermore, our research is investigating the strategic use of the glycerol by-product from the biodiesel production process to generate a hydrogen-rich synthetic gas that can augment the combustion process, be transformed into another biofuel, or even be converted into ammonia for fertilizer. Imagine a self-sustaining biodiesel production facility that powers itself while becoming a localized source of fertilizer.

KS: Describe your lab facilities.

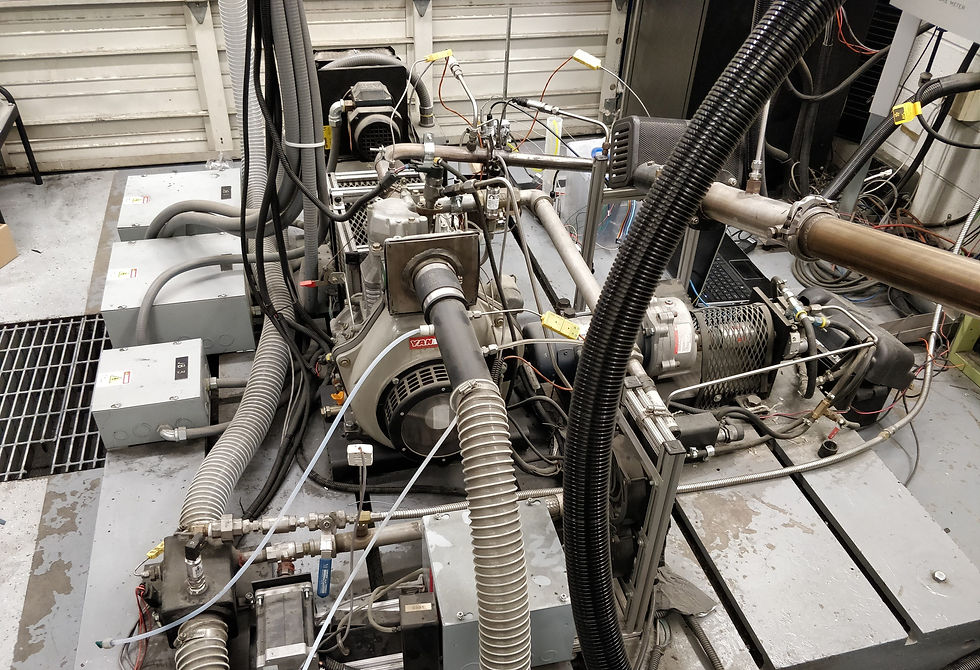

CD: There are three IC engine facilities at the University of Kansas where students hone their skills. Our single-cylinder compression ignition (CI) engine facility allows testing of a wide variant of fuels (both liquid and gaseous-based, everything from alternative jet fuels to Compressed Natural Gas) including the influence of cooled Exhaust Gas Recirculation and high-pressure rail fuel injection. After gaining relevant experience, students can move to our multi-cylinder CI engine test cell to reinforce their findings on a production engine helping to ensure that the fuels tested are pertinent for commercial and regulatory environments. If a non-traditional fuel is being studied, our facilities also include a fuel reformer connected to spark ignition engine and generator. This setup is the only one of its kind to demonstrate glycerol to hydrogen-rich syngas with subsequent combustion and power generation all in one continuous flow process.

KS: What’s your favorite type of flame?

CD: I am a big fan of the premixed combustion phase during compression ignition combustion. To me, there is nothing better than hearing a diesel generate constant volume combustion and high thermal efficiencies. Plus, after driving a diesel vehicle for a few years, that “bang” becomes part of your character. However, I do not believe our neighbors liked hearing it on a cold day early in the morning.

KS: What’s your favorite fuel?

CD: It depends on the engine type. Currently, biodiesel for compression ignition engines and ethanol for spark ignition engines have numerous benefits. However, any fuel that can lessen our dependence on fossil fuels while being ecologically sound and socially pertinent has my vote. Identifying what that fuel is and then designing the engine for its specific properties is what is critical now and in the future.

KS: What advice would you give students thinking about going into combustion research?

CD: Study the fundamentals. Combustion research has been around for over 100 years, so trying to obtain a solid background might seem overwhelming at times. However, the fundamentals never (really) change. If you steep your understanding in the basic facets of combustion (e.g., thermodynamics and heat transfer), you will find that soon you can hold a conversation with those who have been researching the subject for 20+ years. Do not take shortcuts and simply repeat what others have published (e.g., using a model that is readily available). Instead, understand how that research came to be and question the assumptions involved until you can answer your own inquiries. Some of my best work involves revisiting the fundamentals to get better at my craft.

KS: Is the IC Engine dead?

CD: No. There is nothing more power and energy dense to move a lot of mass a long distance. As the engine industry continues to make advances, we are going to see smaller and more powerful engines that emanate less emissions. In addition, battery technology and hybridization are enabling IC engines to achieve greater gains while minimizing their influence. I do not envision IC engines ever completely going away; however, one day, you might look underneath the hood of your vehicle and have a hard time finding them. Imagine a one-cylinder engine that is boosted (multiple times) and runs at a limited number of set points (with specially designed catalytic converters) to charge the battery pack promoting a greater driving range.

KS: How is your work helping improve fuel efficiency or reduce emissions?

CD: A significant amount of our effort revolves around understanding fuel properties and relating those characteristics to efficiency (i.e., combustion, thermal, and fuel conversion) and emissions. This includes normalizing the combustion process to provide a truer picture of these fuels by mitigating the changes in the injection process that occur when a fuel with dissimilar characteristics is tested. For instance, our laboratory has published a few papers that illustrates nitrogen oxides decrease when using biodiesel after accounting for cetane number, fuel density, and other properties. Ideally, this work will help ensure engines are re-designed for biofuel specifics resulting in greater efficiencies with reduced emissions. Furthermore, other current research involves printing titanium engines using Additive Manufacturing (AM). Remarkable fuel economy (and associated emissions) gains are achievable if we can make IC engines lighter and more powerful; hence, AM might revolutionize the way we design engines in the future.

Comments